The modern electronic four-wheel anti-lock braking system (ABS) was first introduced in production vehicles by Mercedes-Benz in 1978 on its flagship S-Class (W116). This digitally integrated brake system, developed jointly with Bosch, revolutionized automotive safety by preventing wheel lock-up during emergency braking.

Key details regarding the introduction of the ABS system.

In 1978, Mercedes-Benz’s S-Class W116 was the first model to offer a multi-channel electronic ABS for all four wheels as an optional feature.

Other early systems: While Mercedes-Benz’s 1978 ABS was the first mass-produced electronic system, Chrysler had introduced the "Sure Brake" system on the 1971 Imperial, and Fiat developed an early electronic control system in 1971 as well, although these were not widely adopted.

Following its launch, Mercedes-Benz gradually made ABS standard across all its models. Subsequently, ABS became the commonly used anti-lock braking system throughout the automotive industry.

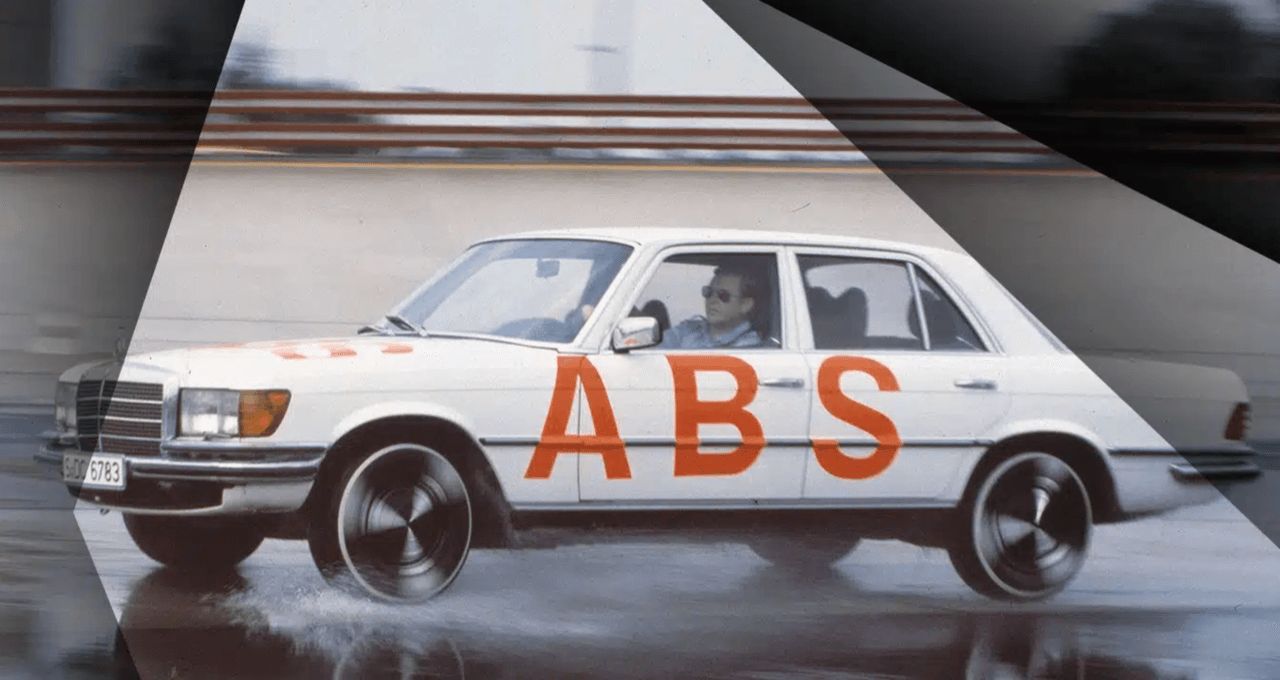

Rewinding to 1978, the introduction of the four-wheel multi-channel anti-lock brake system changed car braking forever. ABS was not only a pioneering safety innovation that helped humans avoid accidents but also opened the door to modern high-performance automotive technology we enjoy today. Remarkably, the concept of ABS braking was normalized and applied to improve braking performance—not just stopping distance but maintaining vehicle stability during emergency stops. Bosch and Daimler began implementing this system on the S-Class W116 in the late 1970s.

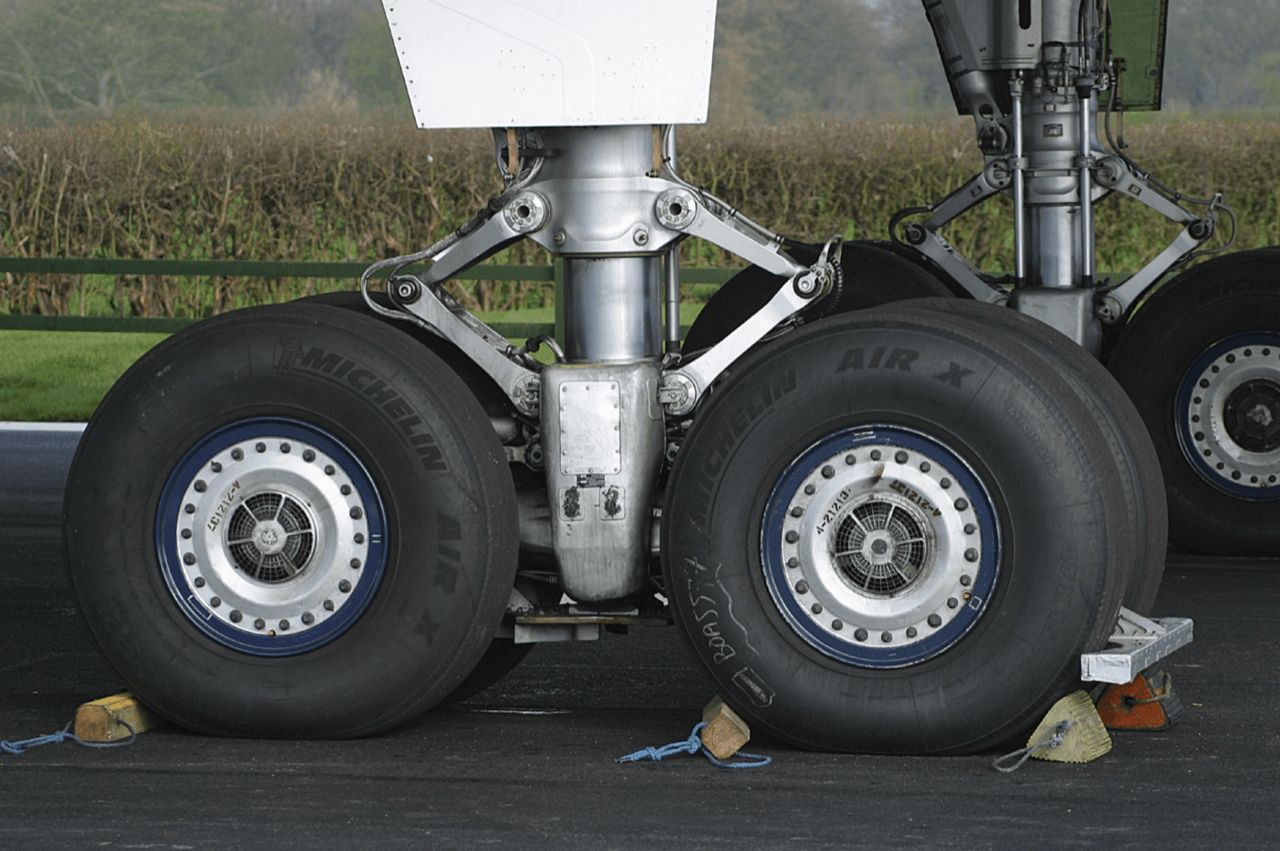

Before World War II, French and German engineers, including Robert Bosch, experimented with anti-skid braking systems for trains and aircraft. In the 1950s, Dunlop, a pioneer in disc brakes, developed a system that improved braking efficiency on British Royal Air Force fighter jets by up to 30 percent. The Maxaret anti-lock brake system was also used on motorcycle prototypes. In the 1960s, Ferguson Research applied ABS to the first four-wheel-drive Formula One car, the P99 with a Climax engine. The UK reached a technological peak by developing advanced electronic wheel-lock control systems for the Concorde aircraft. Naturally, the cost of aerospace ABS research was not an obstacle for building Mach 2.04 jets. The challenge of making ABS affordable and reliable for the automotive industry thus fell to the Germans.

Research at Daimler began in 1953 when Hans Scherenberg, then head of design at Mercedes-Benz, filed a patent application for a system to prevent wheel lock during hard braking. The challenge was that compared to aircraft and trains, cars required more sensors, faster signal processing, and components capable of accurately recording deceleration and acceleration from wheel rotation without errors—even during cornering, uneven surfaces, or slippery roads.

In 1963, Daimler-Benz began developing the electro-hydraulic brake control system. By 1966, Benz partnered with Teldix, a small German electronics company from Heidelberg (later acquired by Bosch). The first brake system debuted in 1970 when Hans Scherenberg presented the Mercedes-Benz/Teldix Anti-Bloc System, an analog-electronic ABS, to the media at the Untertürkheim test track.

Of course, engineers at all automakers worked diligently to justify their salaries and advance innovation. In the US, Chrysler collaborated with Bendix Corporation to develop a computer-controlled ABS called "Sure Brake" for the 1971 Imperial. It performed better than expected. American giant Ford responded with "Sure-Track," an anti-lock braking system installed only on the rear wheels of luxury Lincoln Continentals. GM also entered the safety race by launching an ABS in 1972, initially only for rear wheels, available on Cadillacs and Oldsmobiles.

In Japan, Denso developed an electro anti-lock braking system for the Nissan President, while Toyota produced a similar ABS for its flagship Toyota Crown in 1971. However, the best systems emerged in the late 1970s (1978).

The Benz team went much further to mass-produce a multi-channel ABS for all four wheels. This required digital controllers. As engineer Jürgen Paul, Mercedes-Benz’s ABS project head, noted, choosing digital microelectronics for the second-generation ABS marked a major breakthrough for the brand’s innovation.

By 1978, issues like uncontrollable spinning and understeer—where a car might lose control and veer into oncoming lanes—became less concerning for buyers of Mercedes-Benz S-Class equipped with ABS. Mercedes adopted the slogan "Engineering unlike any other car in the world," and for the W116, emergency braking performance on wet roads truly lived up to that promise.

Mercedes-Benz and Bosch officially launched the ready-to-use ABS technology on the flagship model at Daimler’s test facility in August 1978. The star brand’s brochure stated:

The anti-lock braking system uses a computer to monitor speed changes of each wheel during braking. If a wheel slows too rapidly—such as when braking on slippery surfaces—and risks locking, the computer automatically reduces brake pressure. The wheel then accelerates again, and brake pressure is reapplied. This cycle repeats many times within seconds. Simply put, the brakes rapidly pulse on and off to prevent wheel lock, which can cause loss of control and severe accidents in vehicles without ABS. What Mercedes-Benz did not anticipate then was that four decades later, every new car sold—from the Toyota Corolla to the McLaren Senna—could brake safely and effectively thanks to the evolution of ABS combined with additional brake assist technologies developed over time.

ABS provides humans with fundamental force distribution and steering control during braking. It also enables automakers to program diverse driving modes that today allow varying degrees of tire slip—from minimal intervention to complete deactivation of driver aids, up to full electronic assistance.

Today, ABS works alongside massive aerodynamic components and carbon-ceramic brakes on high-performance cars to achieve incredibly short stopping distances. It allows large, heavy vehicles to corner easily and quickly, converting immense horsepower into ultimate acceleration. ABS sensors and processors also underpin modern traction control and stability systems—from preventing tire spin to making drivers look like heroes on the racetrack.

Of course, intelligent differentials, quality tires, and effective aerodynamics are vital for control, but most of the data fed to the digital brain by sensors returns to the ABS controller, which performs millions of calculations per second—whether in cars, trains, or aircraft.