Maintaining a diesel engine involves regularly changing the engine oil and filters with high-quality products. It also requires inspecting and cleaning air filters and fuel filters (including water separators) regularly, keeping the cooling system in good condition with proper coolant levels, checking belts and hoses, and paying attention to exhaust and emission systems. All these factors are crucial for the engine's longevity and performance.

Diesel engines revolutionized transportation when first introduced in the late 19th century. Over 100 years later, diesel engines remain central to the commercial trucking industry. Their torque performance, fuel efficiency, and durability have made diesel engines an essential power source for modern vehicles. Regular diesel engine maintenance is vital to ensure efficient operation throughout the engine's lifespan.

1. Change engine oil according to schedule

This simple task is often neglected. Clean engine oil is essential for reducing friction and cooling key engine components. Diesel engines produce more soot and pollutants than gasoline engines, causing oil to become dirty faster. Waiting too long between oil changes leads to sludge buildup, increased wear, and reduced performance. Oil changes should follow the lubricant replacement intervals in the manual, with shorter intervals if the engine is heavily used or frequently driven in traffic jams.

2. Regularly replace fuel filters

Fuel filters are critical components in diesel engines. Diesel fuel filters protect injectors from dirt, water, and other contaminants. Because diesel fuel is more prone to contamination than gasoline, most diesel engines have two fuel filters. Replacing filters on schedule ensures a steady supply of clean fuel, preventing injector damage and maintaining fuel injection efficiency.

3. Inspect and clean the cooling system

Diesel engines operate at much higher temperatures than gasoline engines, putting heavy demands on the cooling system. Old coolant can lose its protective qualities, causing corrosion and scale buildup inside radiators and engine passages. Regularly checking coolant levels and flushing the cooling system at appropriate intervals helps prevent overheating and costly engine damage.

4. Frequently check air filters

Diesel engines require large volumes of air to operate efficiently. A clogged air filter restricts airflow, increasing fuel consumption and reducing performance. Driving in dusty conditions or off-road requires more frequent air filter changes. Regular inspections during routine maintenance quickly prevent unnecessary engine strain.

5. Check belts and hoses for wear

Belts and hoses might seem less important than injectors or turbochargers, but a broken belt or burst hose can leave a vehicle stranded. Diesel engines produce significant vibration and heat, accelerating wear. Regular inspections help identify minor issues before they become major problems during operation.

6. Maintain the turbocharger

Turbocharged diesel engines rely on clean oil and proper cooling to function well. Allowing the engine to idle briefly after heavy use gives the turbo time to cool down, preventing premature wear. Regular oil changes and inspections protect turbo bearings from damage.

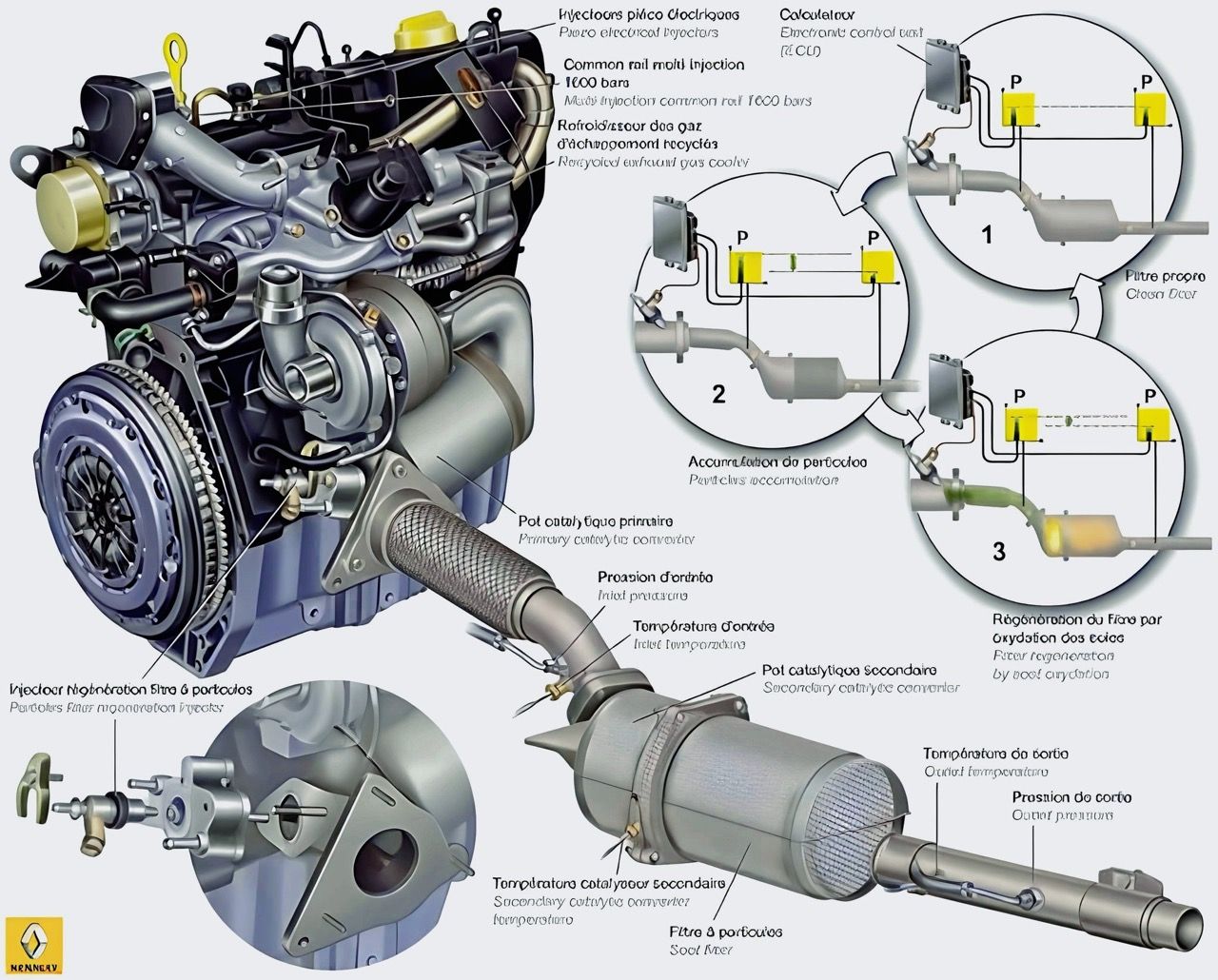

7. Maintain the exhaust treatment system

Modern diesel vehicles use exhaust treatment systems such as Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) systems to reduce emissions. Neglecting these components can lead to clogging, increased fuel consumption, and costly repairs. Using appropriate low-sulfur fuel and following regeneration procedures helps keep these systems operating efficiently. When clogging or soot buildup is detected, professional cleaning at a garage or service center is recommended.

8. Pay attention to warning lights

Diesel engines depend heavily on sensors and computerized Engine Control Units (ECU) for performance management. When the check engine light or engine warning symbol illuminates, do not ignore it. Professional diagnosis quickly identifies issues that, if left unaddressed, could cause engine damage.

9. Have the vehicle inspected by expert mechanics

Even with regular oil and filter changes, professional diesel mechanics can detect overlooked problems. These include injector balance tests, compression checks, turbocharger function, emission system performance, and diesel exhaust fluid refills. Regular inspections help extend engine lifespan.