In the past, shortly after the invention of the internal combustion engine, technological advancements continuously improved engine efficiency and power. Increasing the engine displacement—that is, enlarging the engine's volume to burn more air and fuel—was one way to boost horsepower. Another method was to keep the displacement the same but force more air and fuel into the engine using a turbocharger or supercharger system.

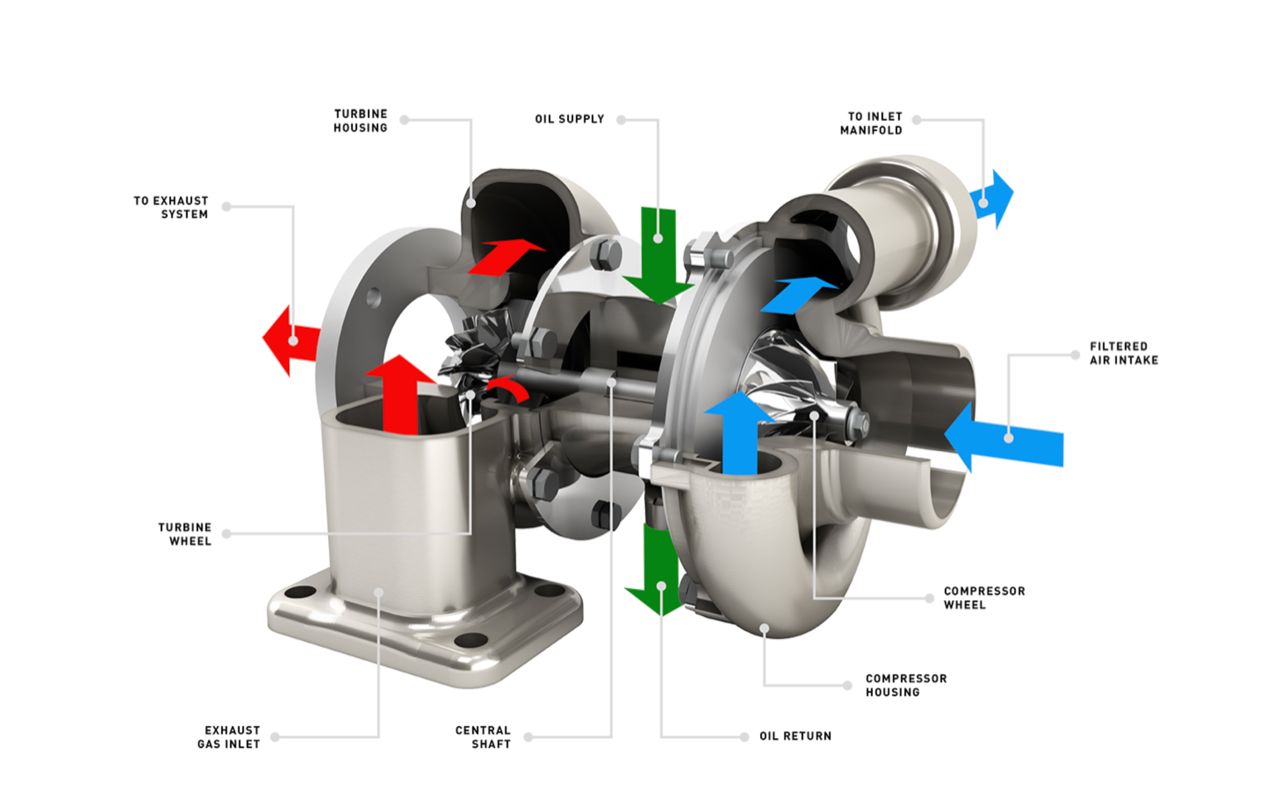

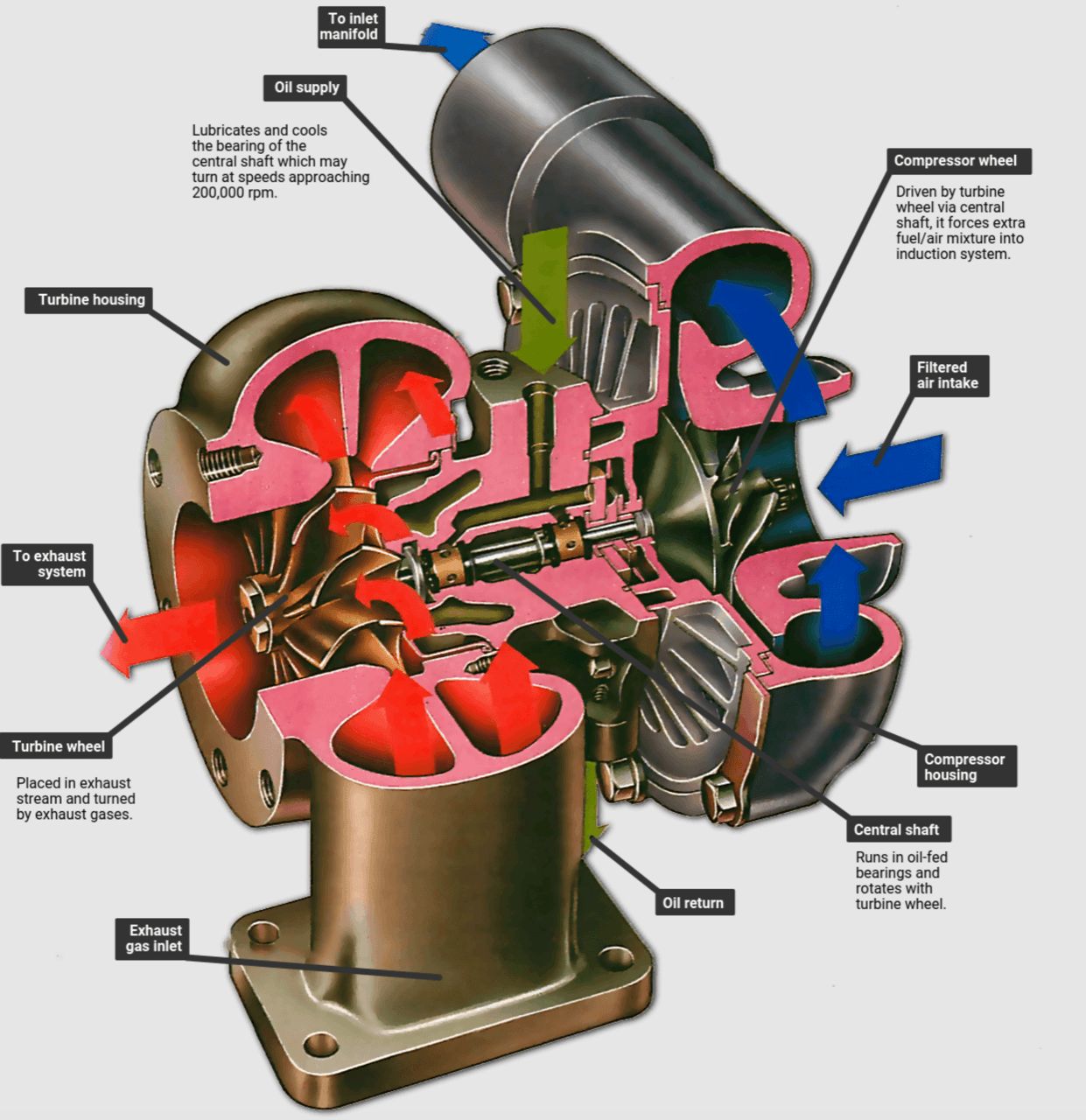

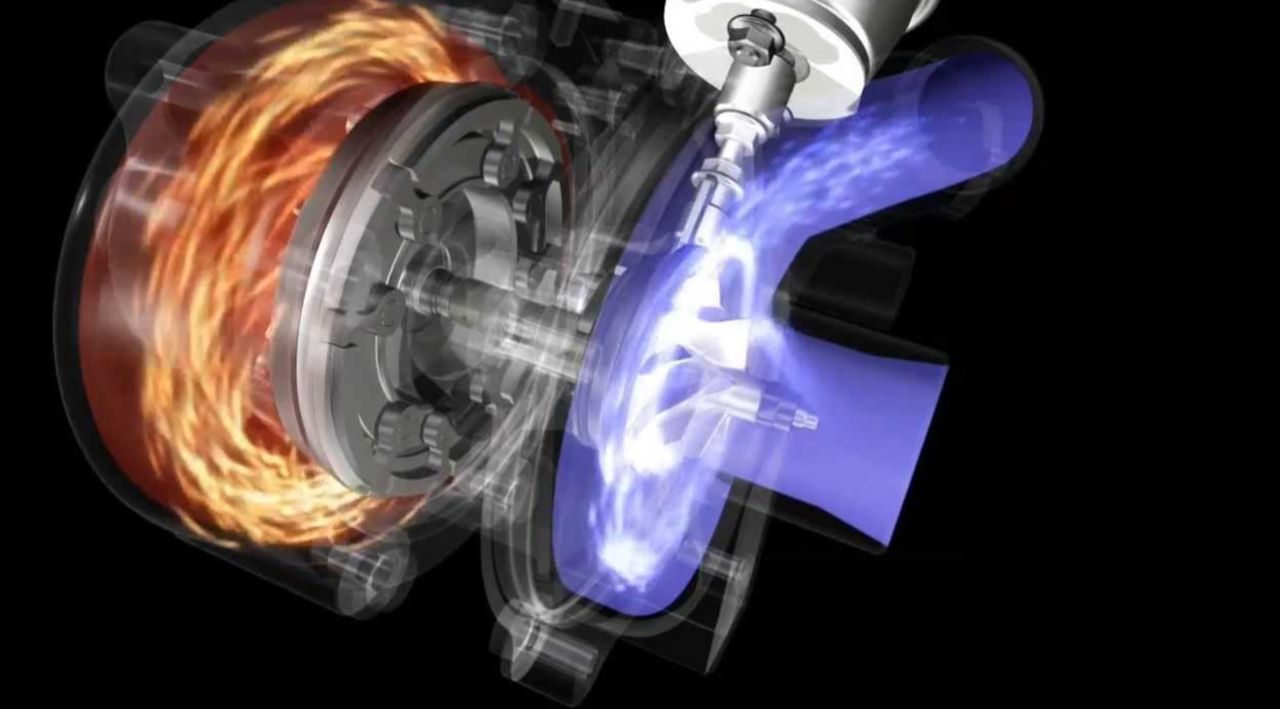

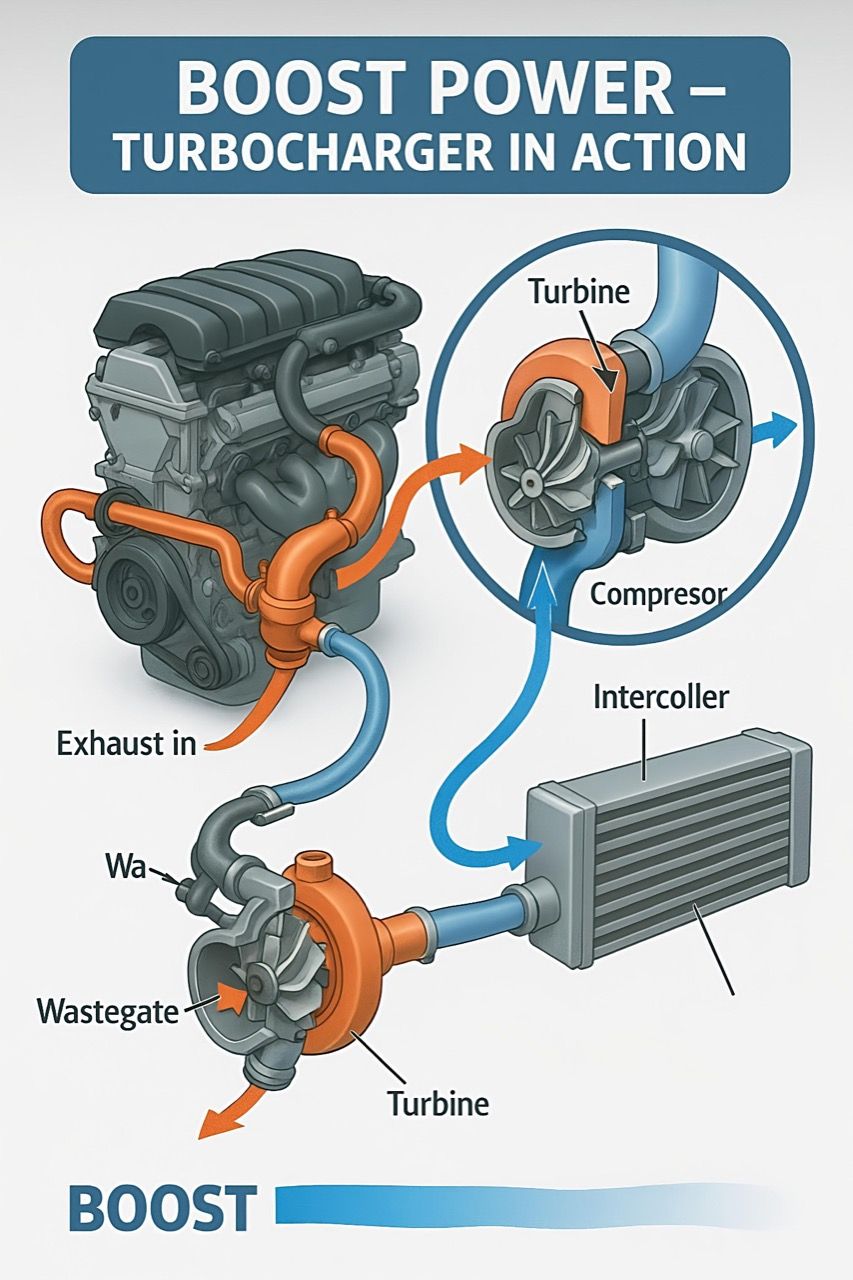

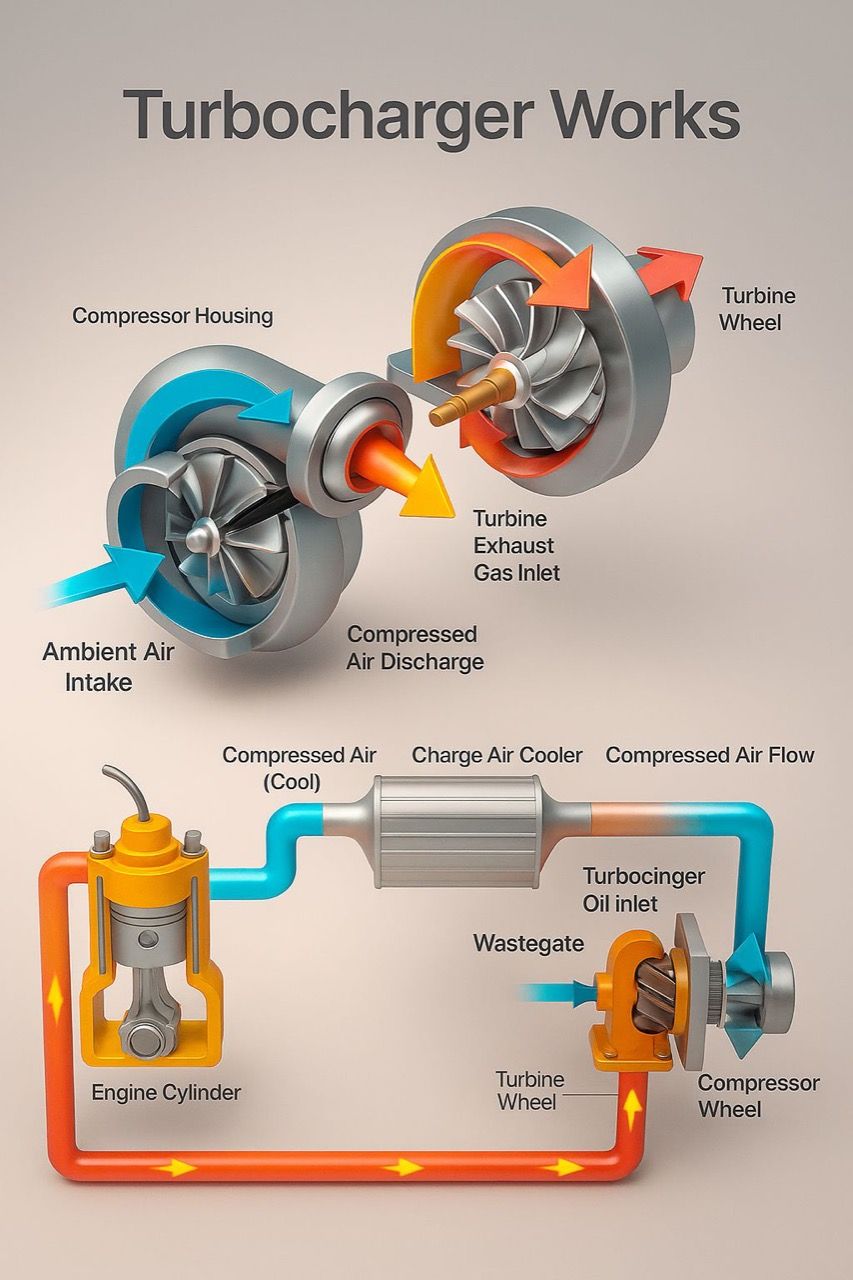

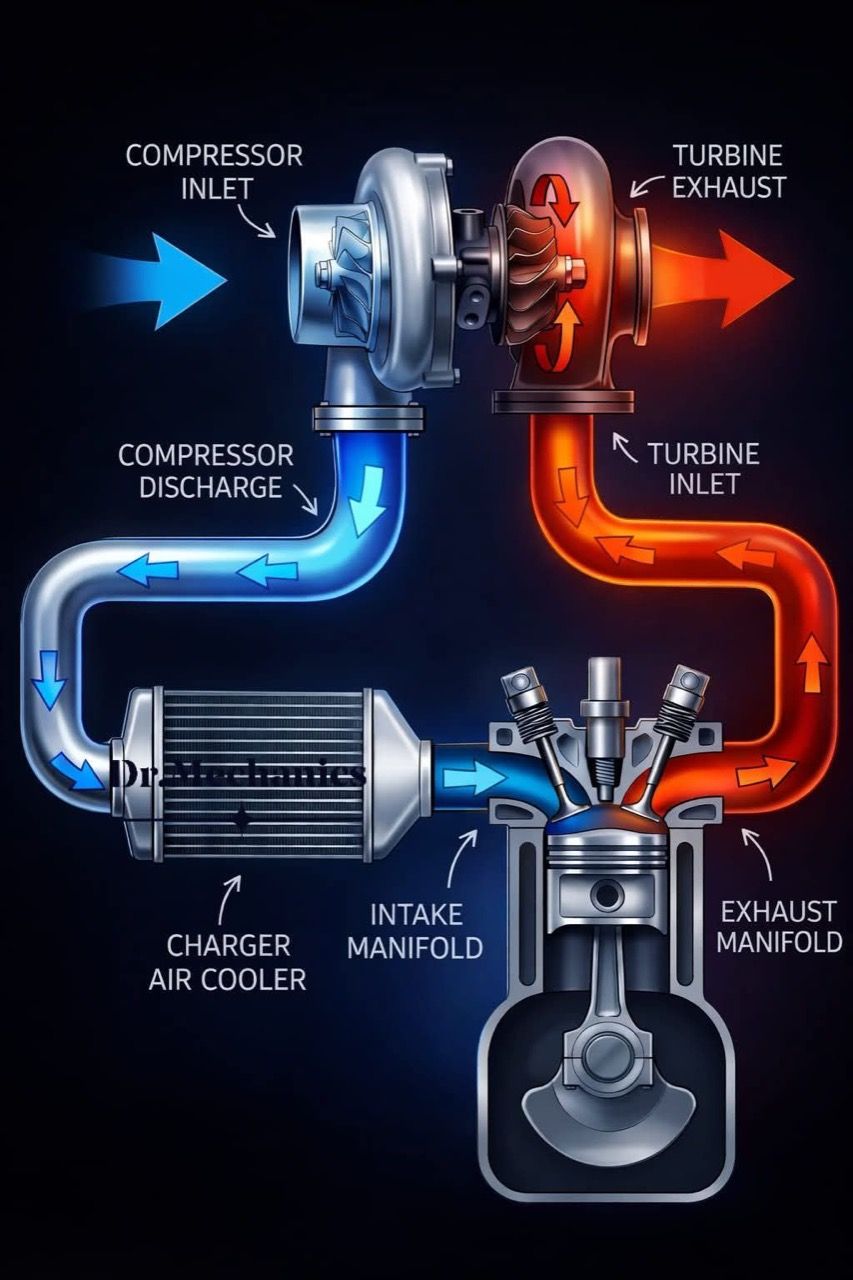

A turbo is an air compression system that increases engine horsepower and torque. It connects to the exhaust manifold where exhaust gases flow from the cylinders, using exhaust pressure to spin a turbine wheel. The exhaust then exits through the exhaust pipe. At the other end of the turbine shaft is a compressor wheel that spins simultaneously, drawing air into the compressor housing to compress fresh air into the engine cylinders. This air mixes with fuel and ignites to produce torque. Naturally, the more air-fuel mixture entering the cylinders, the greater the horsepower output.

Today, internal combustion engines equipped with turbocharger air compression systems are popular and vital for increasing horsepower. Modern turbo engines not only enhance performance in smaller engines but also reduce fuel consumption. The added horsepower is a key reason turbos are popular in racing and high-performance sports cars, and this technology has expanded to everyday diesel and gasoline vehicles. The question "How much horsepower can a turbo add?" is no longer just about power. Modern electric turbos also improve low-end acceleration and fuel economy, enabling smaller 1.6 to 2.0-liter engines to achieve high efficiency.

What is a turbocharger?

A turbocharger is a type of air compression system that pressurizes the air entering a car's engine. The advantage of compressing air is that it allows the engine to force more air into the cylinders. More air means more fuel can be mixed, resulting in greater power from each explosion in the cylinders.

Turbocharged engines produce more overall power than naturally aspirated engines of the same size, significantly improving the power-to-weight ratio. Small engines become more efficient power sources, meaning less frequent refueling is needed despite increased power. The turbocharger uses exhaust gas to spin a turbine, which then drives the air compressor. The turbine spins at speeds between 80,000 and 200,000 rpm—up to 30 times faster than the engine speed. Because the turbine is connected to the hot exhaust, turbocharged cars operate at higher temperatures than naturally aspirated vehicles.

One of the surest ways to improve engine performance and increase power is to raise the amount of air and fuel that can be burned thoroughly and quickly. Increasing cylinder count or enlarging cylinder size can achieve this, but such modifications are difficult. A turbocharger provides a shortcut to boosting power, offering a simpler and more compact mechanical advantage.

A turbocharger increases the amount of fuel and air burned in the cylinders by compressing them before intake. Typical boost pressure from a turbocharger is between 6 and 8 psi. Since atmospheric pressure at sea level is 14.7 psi, this means the engine receives about 50% more air. One might expect a 50% power increase, but due to turbocharger inefficiencies, a 30 to 40% power gain is more realistic for everyday use.

The horsepower increase from a turbocharger depends on several variables such as turbo size, engine type, and turbo tuning. For example, if a base engine produces 200 horsepower, a turbocharger might boost it to 240–280 horsepower or more. One reason for less-than-ideal efficiency is that the energy to spin the turbine is not free. The turbine adds backpressure to the exhaust system, meaning the engine must push against higher exhaust pressure during the exhaust stroke, slightly reducing the power output of the working cylinders.

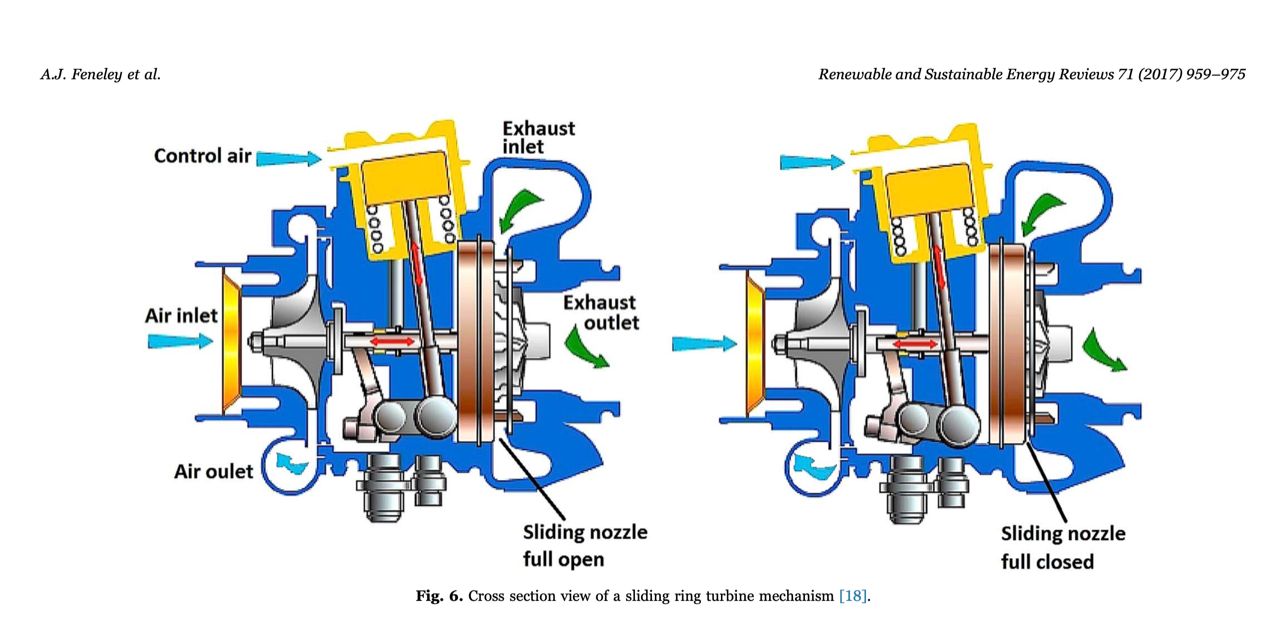

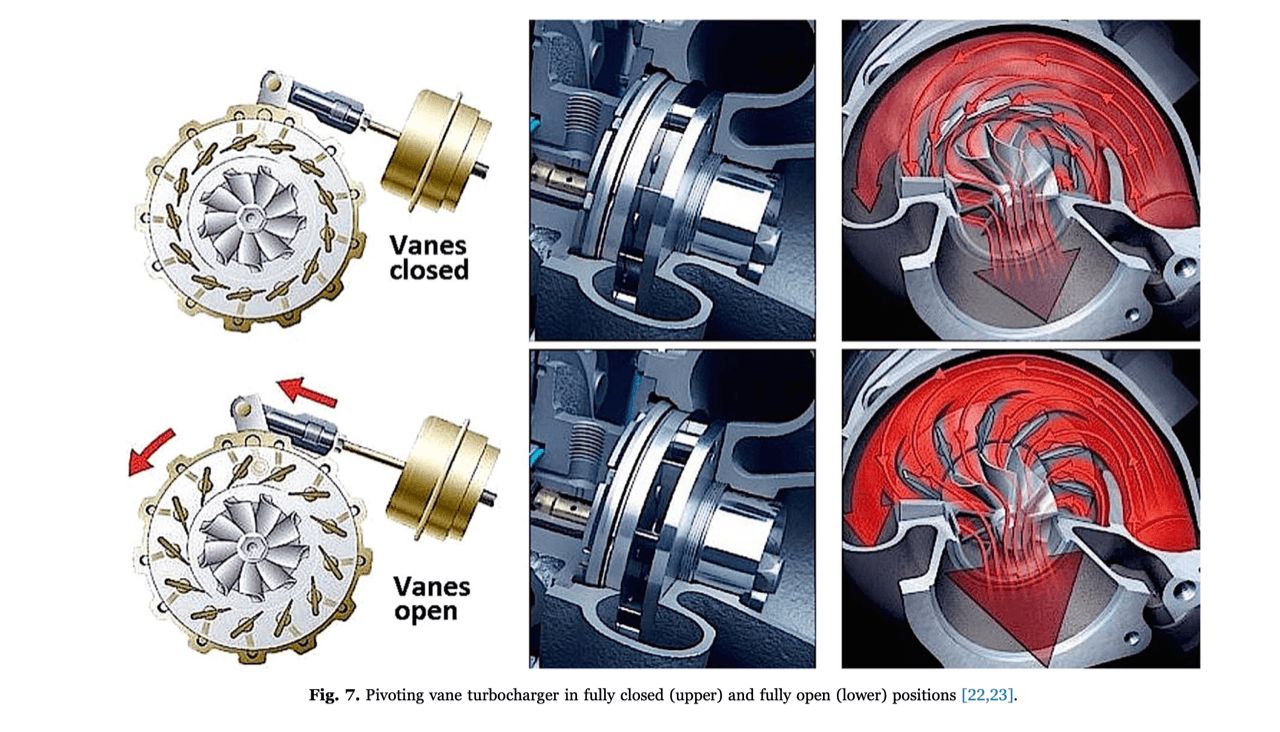

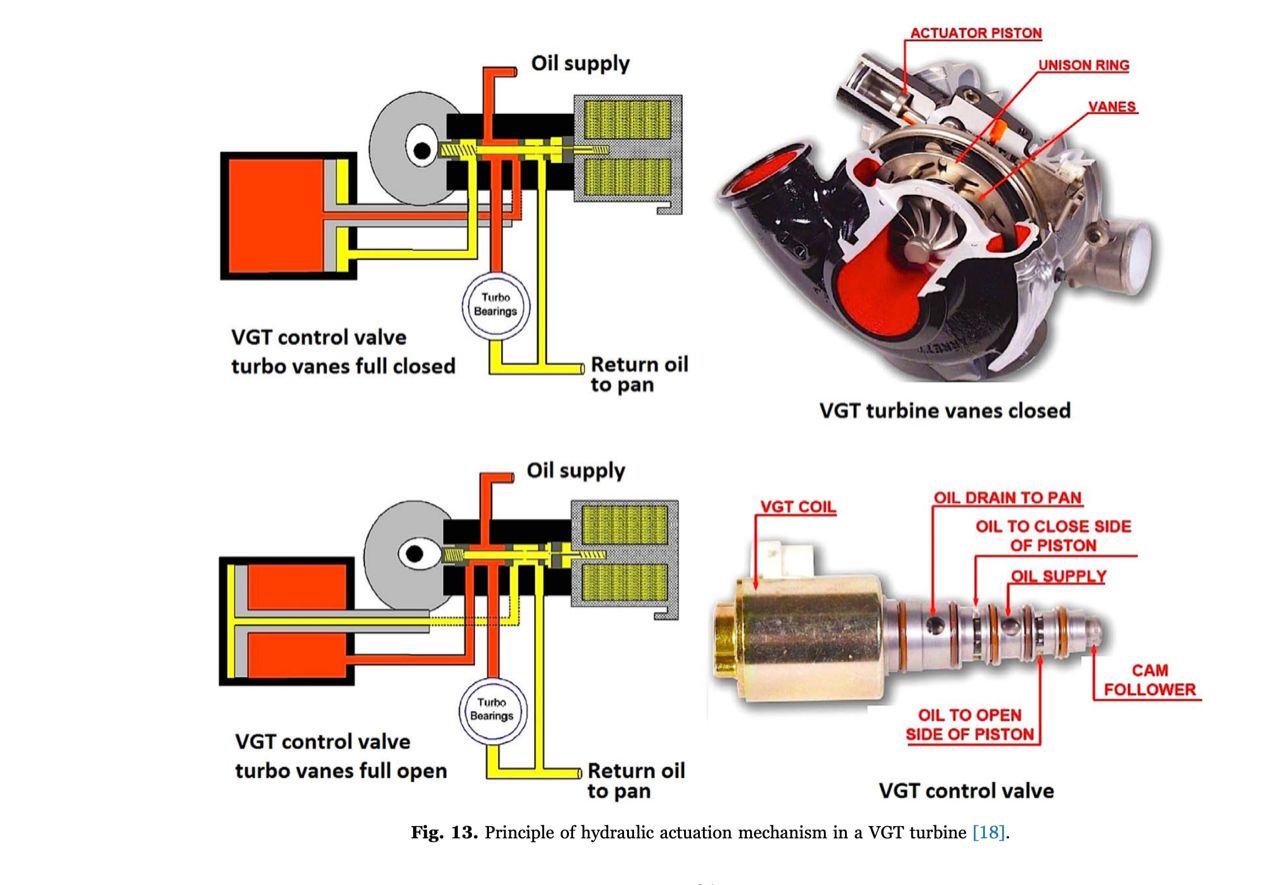

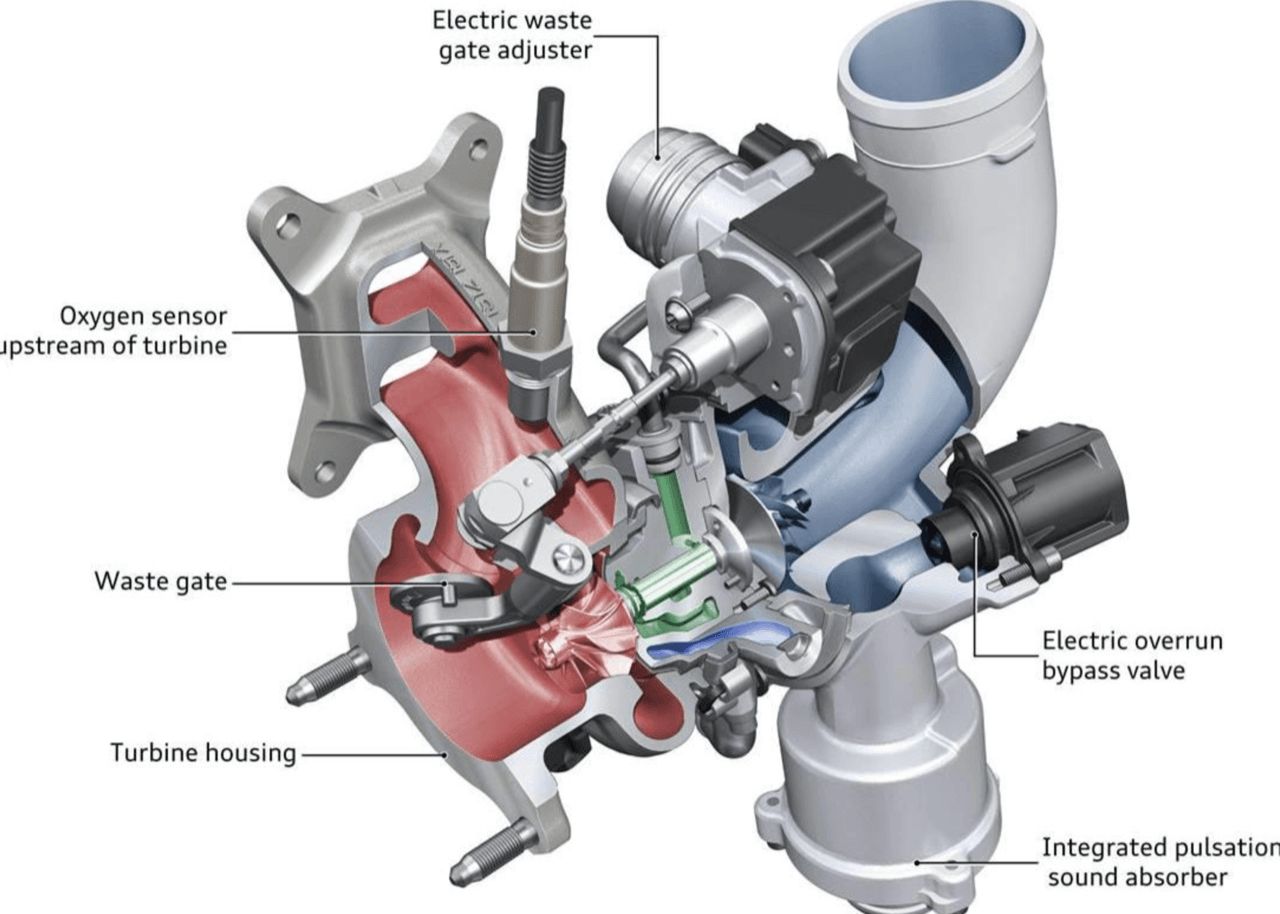

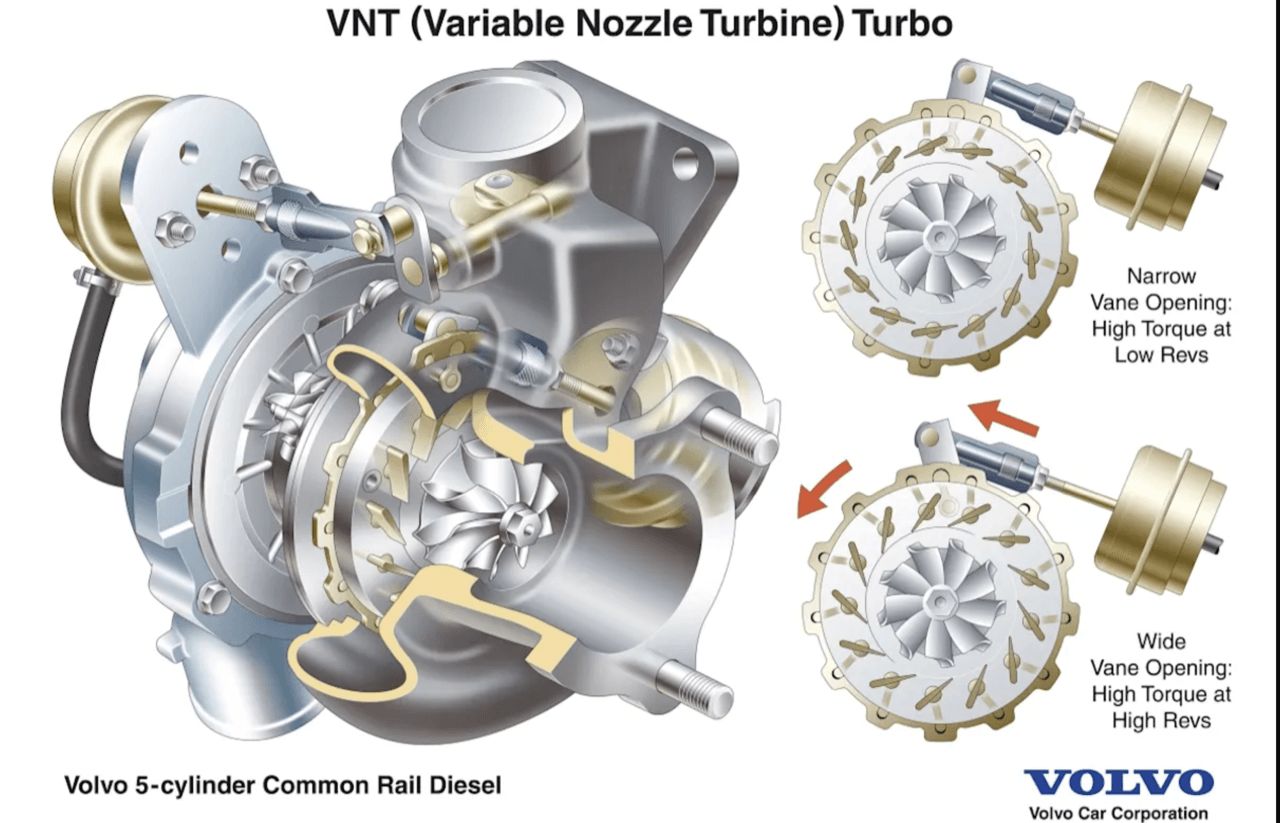

Most automotive turbochargers include a wastegate valve to reduce turbo lag in small turbos and prevent the turbine from over-speeding at high engine RPMs. The wastegate is a valve that allows some exhaust gases to bypass the turbine blades. It monitors boost pressure, and if the pressure gets too high causing the turbine to spin too fast, the wastegate opens to divert some exhaust around the turbine, slowing it down.

Some turbochargers use fluid bearings instead of conventional bearings to support the turbine shaft. These are not ordinary bearings but highly precise, advanced-material bearings designed to withstand the turbocharger's high speeds and temperatures. Fluid bearings reduce friction compared to conventional bearings used in most turbos. They also allow for smaller, lighter turbine shafts, enabling the turbocharger to spool up faster and reduce turbo lag.

An intercooler, or compressed air cooler, is an additional component resembling a radiator but distinct in that air flows both inside and outside the intercooler. The intake air passes through sealed internal channels, while cooler external air is blown across the fins by the engine's cooling fan.

The intercooler increases engine power by cooling the compressed air exiting the compressor before it enters the engine. For example, if the turbocharger operates at 7 psi boost, the intercooler delivers cooler air at 7 psi, which is denser and contains more air molecules than warmer air.

Modern car fuel injection systems use oxygen sensors in the exhaust to monitor the air-fuel ratio for accuracy. The system automatically increases fuel flow when a turbocharger is installed. However, if a high-boost turbocharger is installed on a fuel-injected car, the system may not supply enough fuel. This could be due to the control unit's programmed software limits or insufficient capacity of the fuel pump and injectors. In such cases, other modifications are necessary to fully benefit from the turbocharger.

The intercooler, or charge air cooler, resembles a radiator but differs in that air flows both inside and outside the intercooler. Intake air passes through sealed internal channels, while cool external air is blown across the fins by the engine's cooling fan.

The intercooler boosts engine power by cooling the compressed air from the compressor before it reaches the engine. For instance, if the turbocharger produces 7 psi boost, the intercooler supplies cool air at 7 psi, which is denser and has more air molecules than uncooled warm air.

Current fuel injection systems use oxygen sensors installed in the exhaust to check the air-fuel ratio during operation. The system automatically increases fuel flow when a turbocharger is fitted. However, if a turbocharger with excessive boost pressure is installed on a fuel-injected car, the system may supply insufficient fuel. This can result from the control unit's programmed software or the fuel pump and injectors not being capable of adequate supply. In such cases, additional modifications are required to maximize the benefits of the turbocharger.

Twin Turbo vs. Single Turbo: Which Offers Better Performance?

For enhancing engine performance, twin-turbo and single-turbo systems are two popular choices. To determine which is best for your vehicle, consider the following factors:

Power goals: A single large turbo may provide the highest horsepower increase. Larger turbos can generate more power but may have more turbo lag.

Driving style: Twin turbos are preferred for driving that demands peak performance (such as racing) because they deliver better power and acceleration at low engine speeds. Smaller turbos spool faster, offering improved low-end power and acceleration.

Budget: Twin-turbo setups are more expensive than single-turbo systems since they require two turbos and many additional components.

Ease of installation: Single turbos are easier to install due to their simpler design, while twin-turbo systems are more complex.